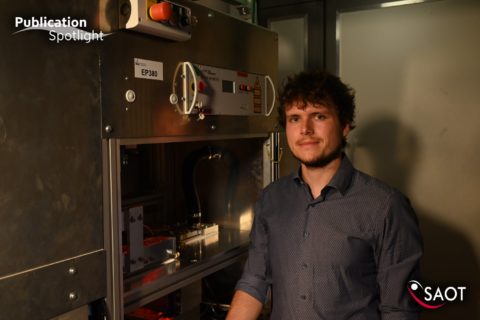

Sebastian-Paul Kopp: Spatially resolved powder deposition for 3D printing

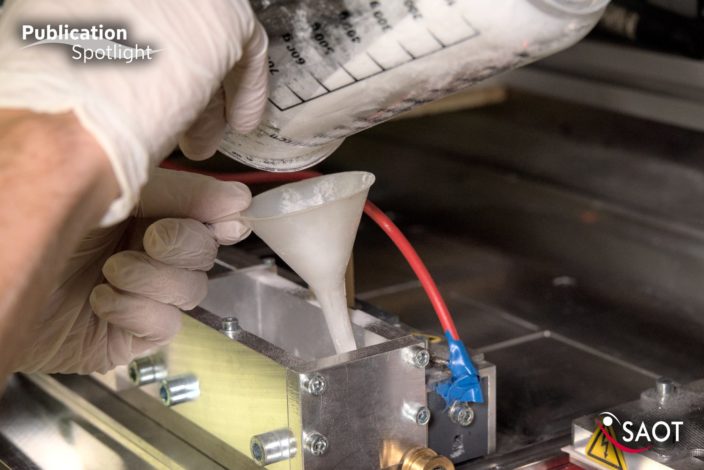

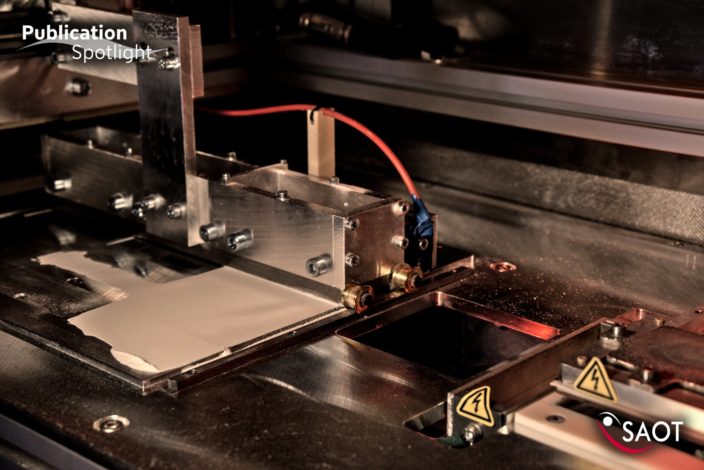

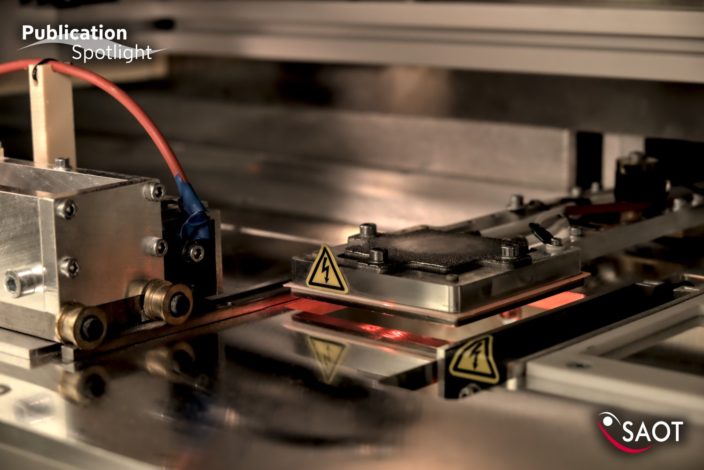

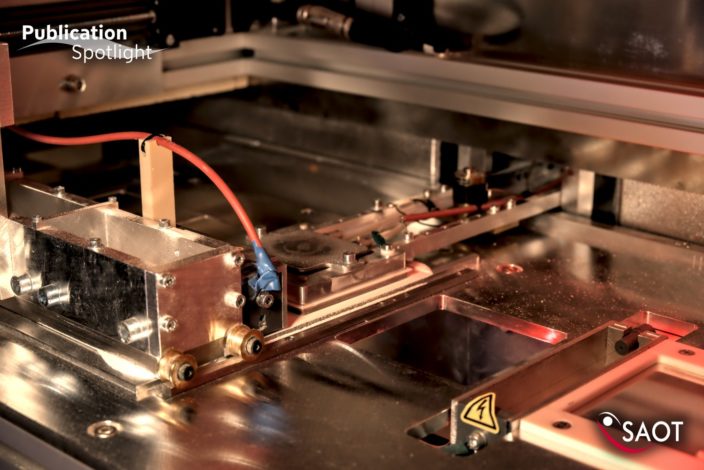

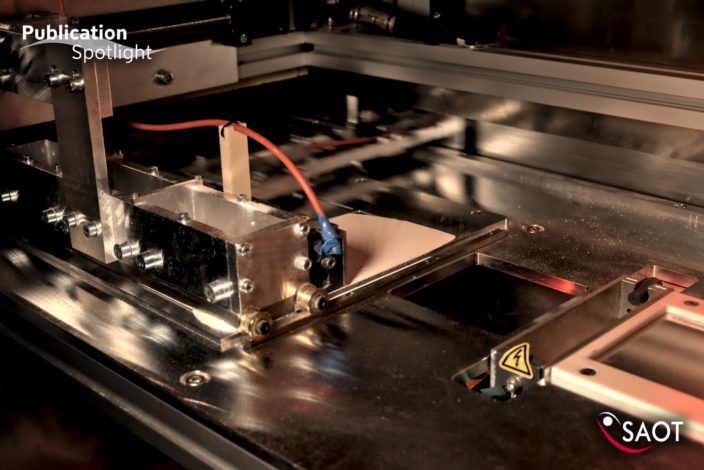

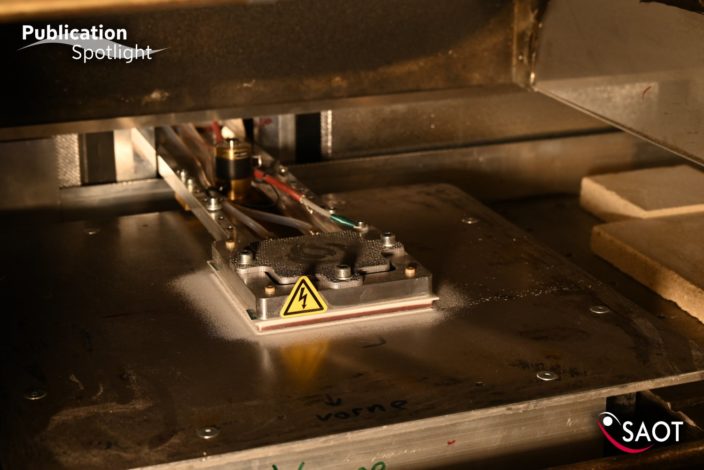

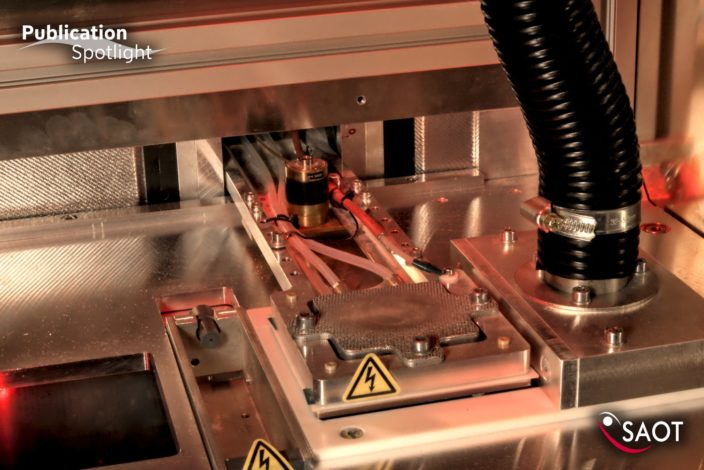

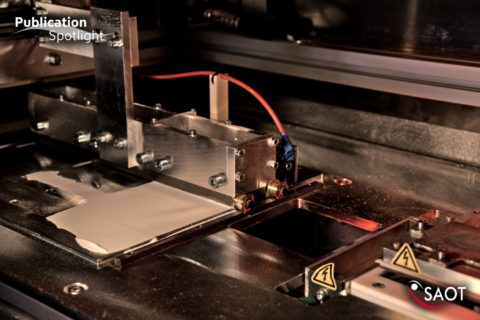

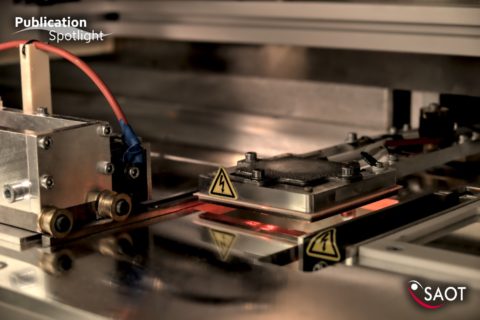

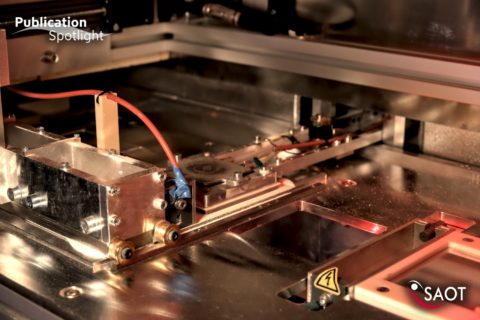

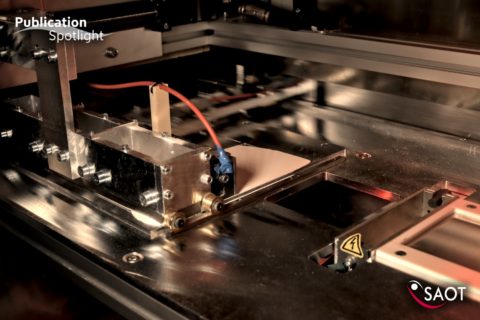

Sebastian-Paul Kopp works on a new technique for powder deposition in laser-based additive manufacturing. Similar to the principle of a laser printer, a light-induced charge pattern on a photoconductive plate allows a spatially resolved distribution of polymer powder on the build platform. This reduces the amount of material needed and enables the fabrication of multi-material parts as well as a decrease of the layer thickness. He published his latest results in the paper “Expanding the Capabilities of Laser-based Powder Bed Fusion of Polymers through the use of Electrophotographic Powder Application.”

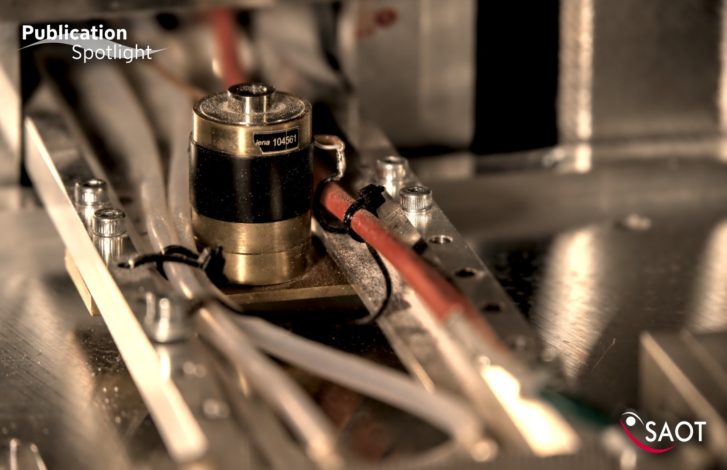

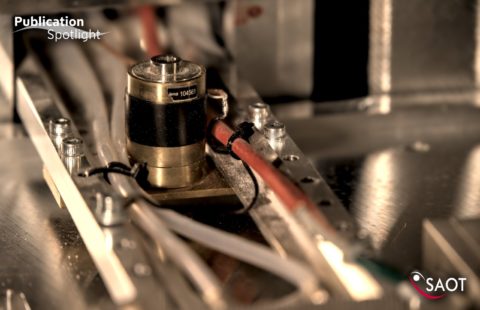

To increase the efficiency and reliability of the powder deposition, Sebastian simulated and successfully implemented a piezo-based vibration of the photoconductive plate. This work is presented in the publication “Targeted Vibration Excitation for Increasing the Powder Deposition Efficiency in Electrophotographic Powder Application for Laser-based Powder Bed Fusion of Polymers”.

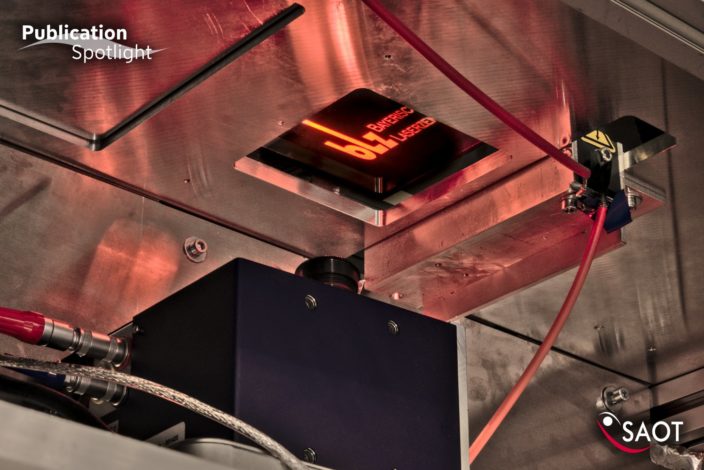

Sebastian works at Bayerisches Laserzentrum (blz), his supervisor is Michael Schmidt. The original publications can be found in the Journal of Laser Applications and in Procedia CIRP.