Alexander Wittmann: Directed energy deposition in thermoplastic polymers

Last year, Alexander Wittmann introduced a laser with a wavelength of 1.94 µm for the consolidation of thermoplastic polymer coatings on metallic substrates. Since light of this wavelength is absorbed in the polymers themselves, light-absorbing additives are not required for the coating process. This is of importance e.g. in the medical sector, where highly pure materials are required.

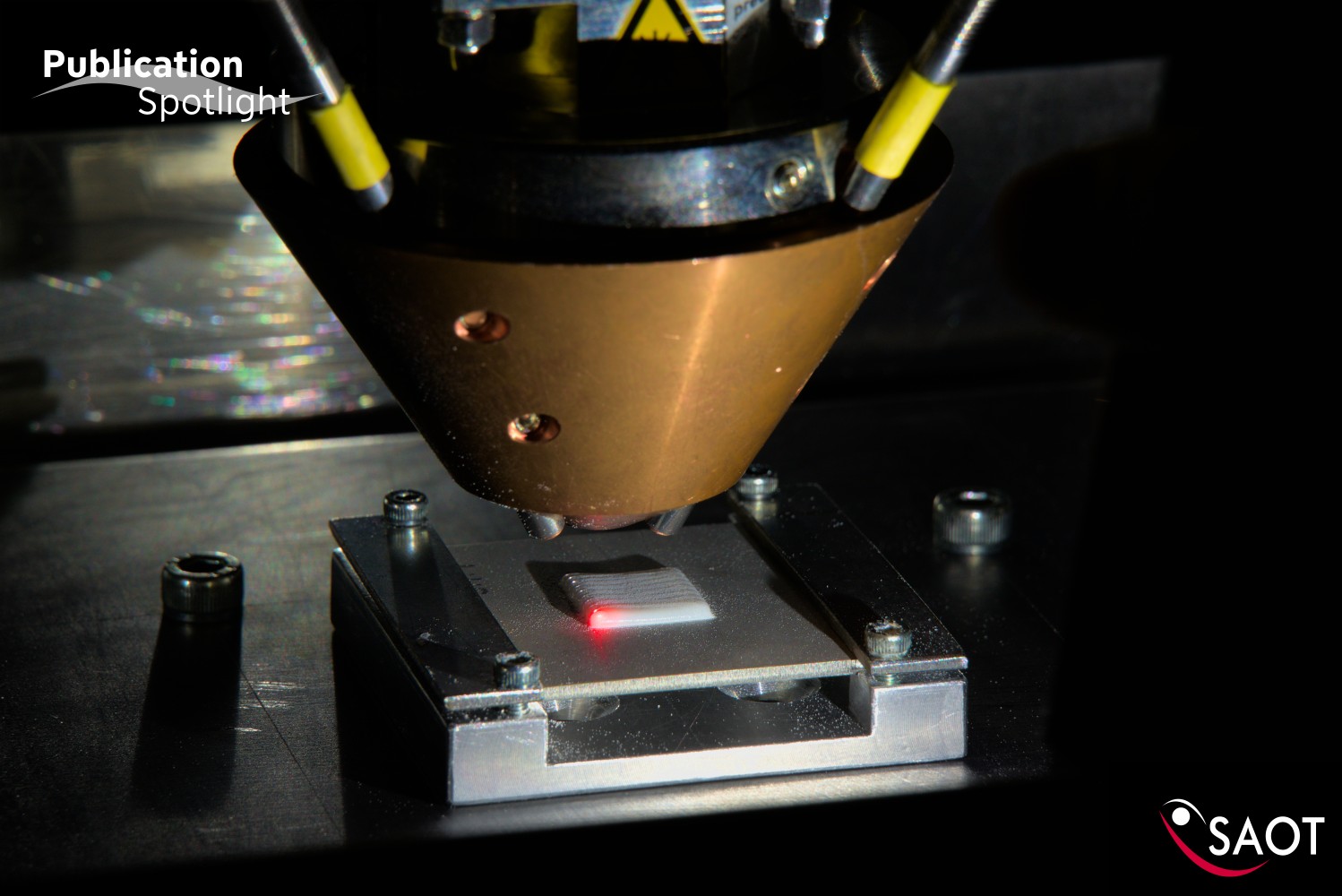

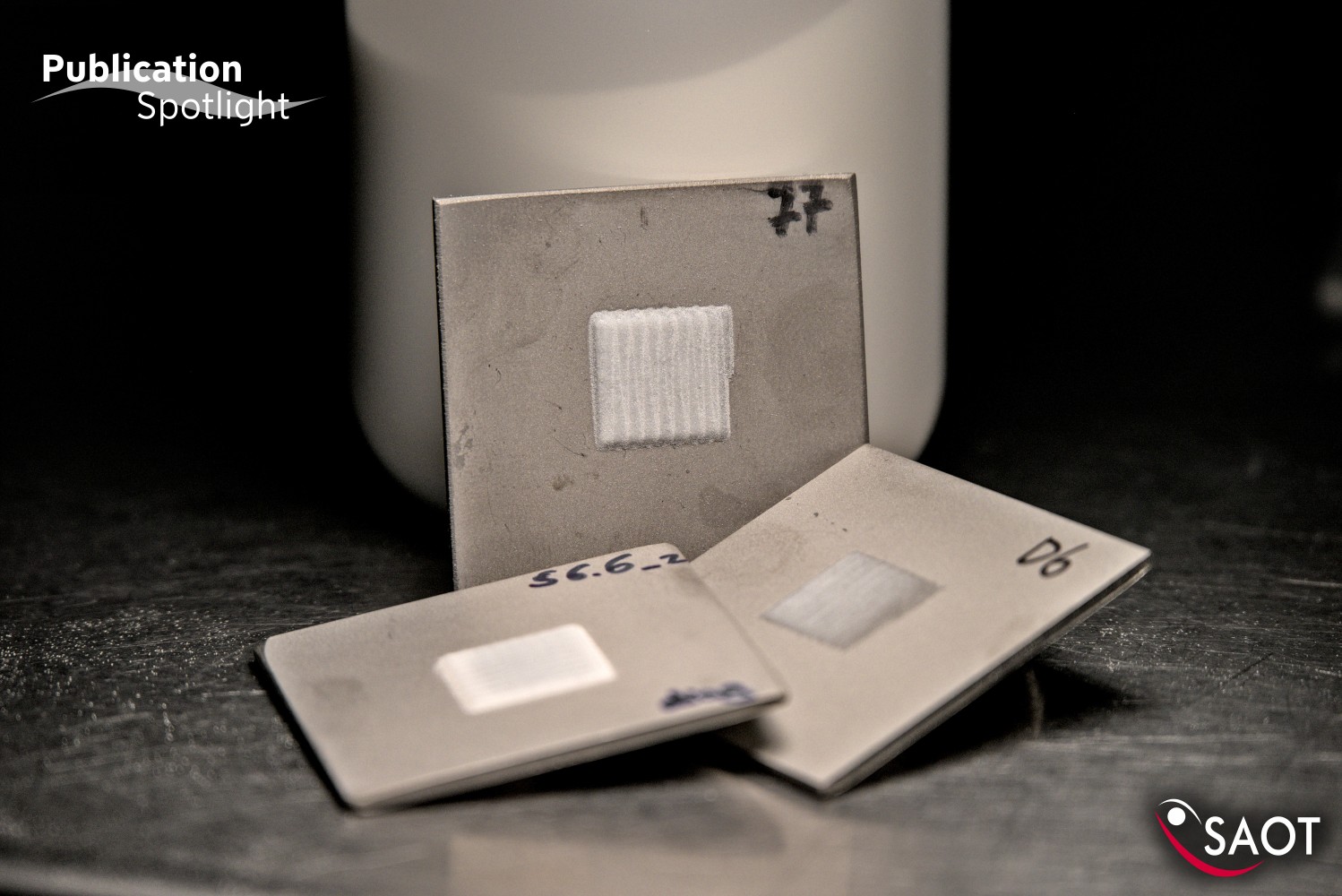

In his detailed follow-up study “Generation of Polyamide 12 Coatings on Stainless Steel Substrates by Directed Energy Deposition with a Thulium-Doped Fiber Laser (DED-LB/P)”, Alexander used this laser beam source to apply polymer coatings to stainless steel substrates for the first time. He analyzed the influence of different parameters on the resulting layer characteristics by in-situ infrared thermography, microscopy and differential scanning calorimetry. His results prove the feasibility of this manufacturing process for the fabrication of adherent coatings with a low porosity. Compared to conventional coating processes (e.g., electrostatic powder spraying and flame spraying), Alexander’s approach enables a shortening of the process chain and a spatially resolved polymer deposition.

Alexander Wittmann works at the Institute of Photonic Technologies, his supervisor is Michael Schmidt. The original publication can be found in Polymers.