Sebastian-Paul Kopp: Advanced 3D printing with charged particles

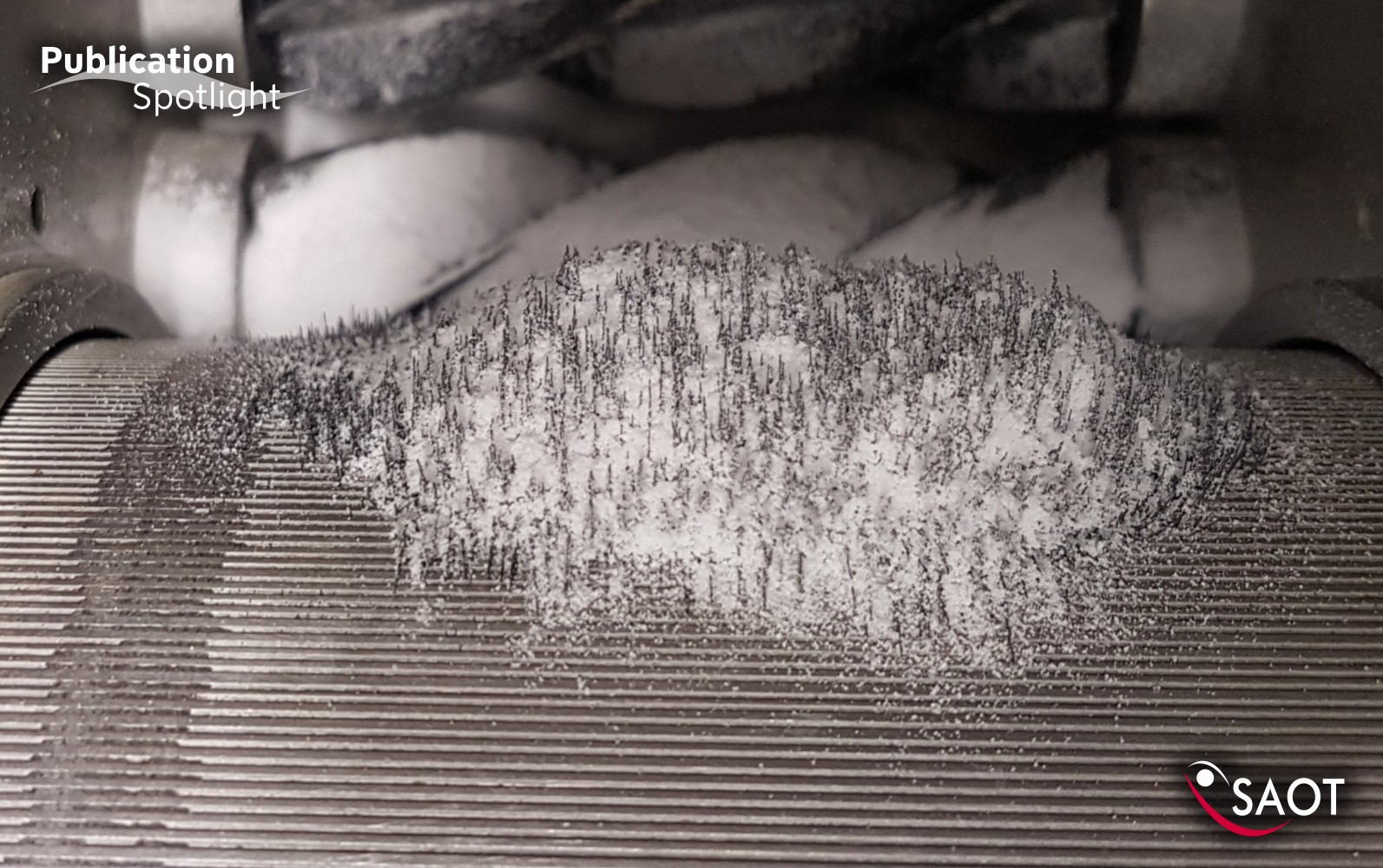

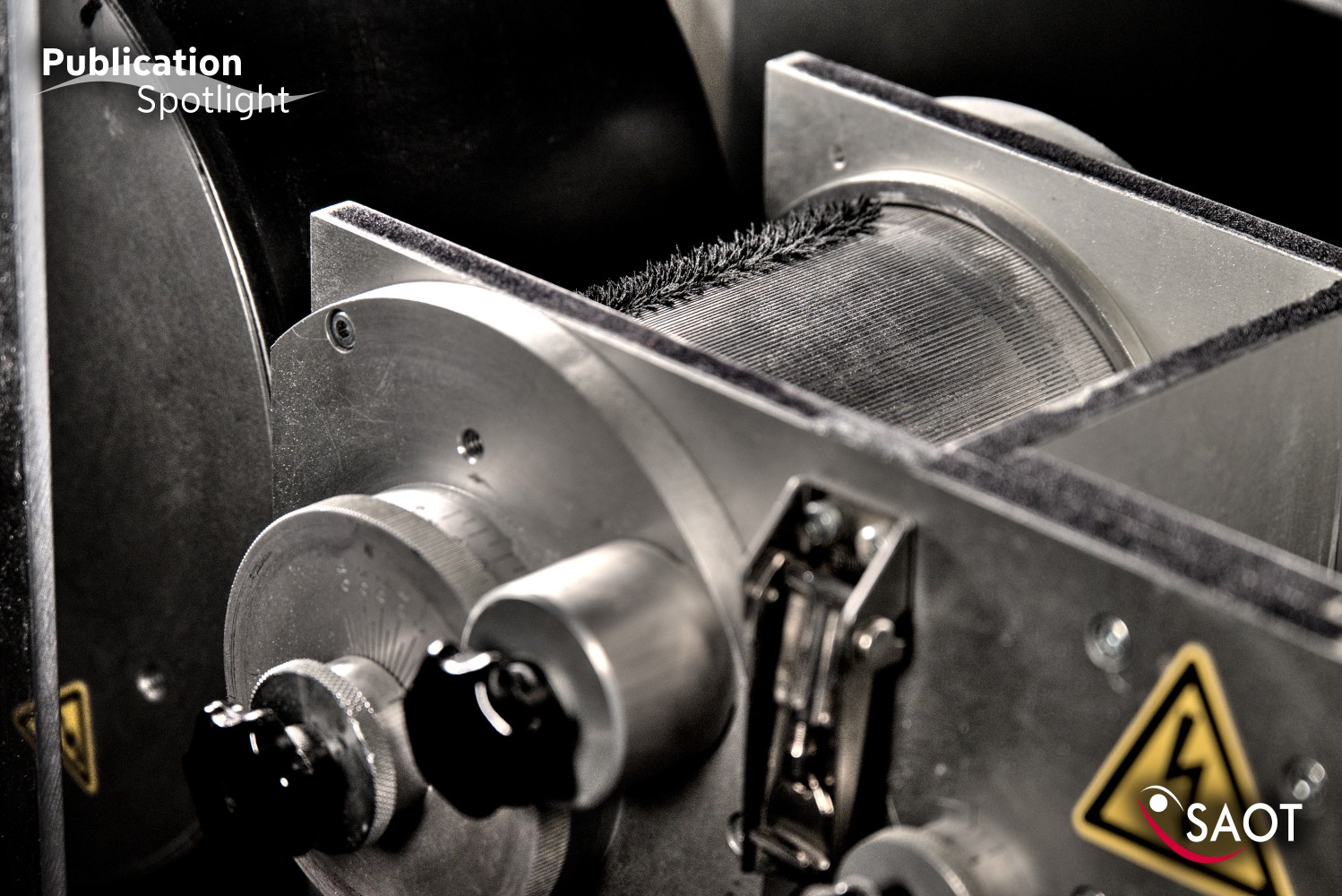

Last year, Sebastian-Paul Kopp introduced a new technique for powder deposition in laser-based additive manufacturing of polymer structures. He transferred charged polymer particles to the build platform using a locally charged photoconductive plate. This enables high powder efficiency and the printing of individually structured shapes.

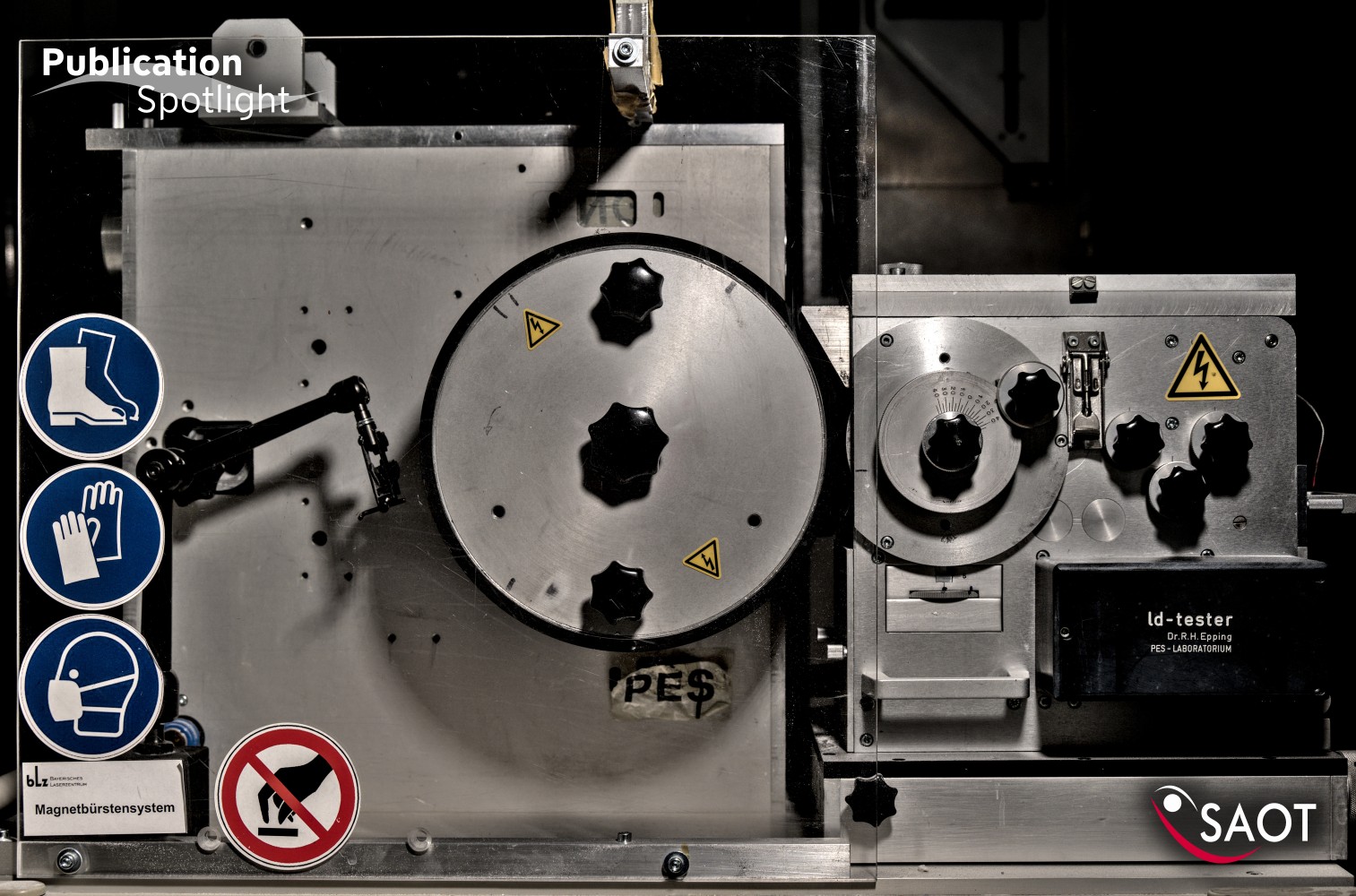

In his recent publication, “Enabling triboelectric charging as a powder charging method for electrophotographic powder application in laser-based powder bed fusion of polymers by triboelectric charge control”, he presents a new method for controlling the charging of the polymer powder. He therefore both tunes the particle surfaces and adds carrier particles. Again, this approach was inspired by the working principle of a common laser printer. As Sebastian shows in his comprehensive study, it enables precise tuning of the process parameters for electrophotographic powder application of different polymer materials in laser-based powder bed fusion.

Sebastian works at Bayerisches Laserzentrum (blz), his supervisor is Michael Schmidt. The original publication can be found in Additive Manufacturing.